START TYPING TO SEE PRODUCTS YOU ARE LOOKING FOR.

0

Your shopping cart is empty.

The name Power Stroke refers to Ford’s family of truck diesel engines produced since 1994—built with heavy hauling, towing, and long-haul durability in mind. Over the years, certain generations (especially the 7.3L) earned legendary status, while others (like the 6.0L and 6.4L) became known for “great power… but with strings attached.” This guide breaks down the Power Stroke timeline, key specs, common issues, and practical performance tips.

Quick Answer: What are the main Power Stroke generations?

Jump to:

The name Power Stroke refers to a family of truck diesel engines that have been produced by Ford Motor Company since 1994, with Navistar International producing them until 2010. Starting in 2011 the 6.7 L Power Stroke V8 was designed and produced solely by Ford.

Over the years, the Ford Power Stroke diesel has earned many die-hard fans, with some versions of the engine becoming renowned for durability and reliability. Almost three decades after its initial release, the 7.3 L Power Stroke is well regarded. Of course, the Power Stroke has had some issues as well, resulting in a fair number of detractors.

The Power Stroke is a family of diesel engines produced by Ford (and historically Navistar) for use in the Ford F-Series trucks and E-Series vans. These diesels are predominately a V8 configuration and feature direct injection and intercooled turbo charging. Marketed towards the heavy hauling consumer segment, Power Strokes have become a household name among pick-up truck enthusiasts.

The Power Stroke made its debut late in 1994, but its lineage actually goes back more than a decade further to 1982. At that time, Ford began making diesel engines in partnership with the International Truck and Engine Corporation (ITEC).

Their first engine was a 6.9 L indirect injection (IDI) engine which produced 170 hp and 315 pound-feet of torque, which was impressive for its time. This engine continued to be produced for several years, eventually being replaced by the 7.3 L IDI engine.

The engine produced between 1987 and 1993 was a 7.3 L IDI engine which used the same stroke as the previous one, though it had a larger bore. It had a stronger engine block and redesigned cylinder heads, but no turbocharger. This engine laid the groundwork for the 7.3 L Power Stroke.

1994 Ford F-250 XL HD XLT 4WD 5 speed manual 7.3L V8

In 1993, a 7.3 L with a turbocharger was released. Although it had been strengthened to endure the pressure of turbo boost, it didn’t actually feature much of an increase in torque or power. The next year, however, saw a significant change with the arrival of the first Power Stroke.

Ford’s first Power Stroke arrived in 1994 and remained in production until 2003. Although the displacement in this new engine was the same as the previous one, it had an electronically-controlled direct-injection system that allowed it to make as much as 21,000 psi. This engine had a 4.11-inch bore and 4.18-inch stroke. The block and cylinder heads were cast iron, and the connecting rods were forged steel. It was durable enough to frequently reach or surpass 300,000 miles.

The 7.3-liter V-8 powered Ford F-250s/350s from 1994 to 2003

In 1999, the next 7.3 L Power Stroke arrived, featuring an air-to-air intercooler and HUEI (Hydraulically Actuated Electronic Unit Injection) fuel injectors. These injectors were a key element of the next-generation Power Stroke. Two oil pumps were required for the new system, one low-pressure and one high-pressure. The low-pressure pump provided oil to the reservoir of the high-pressure pump, which would then force it through oil lines into the high-pressure oil rails. With an injection pressure between 100 and 3,000 psi, the result was an increase in fuel pressure at the injectors.

Like the first generation, this was a durable engine that often reached over 250,000 miles. It stayed in production through 2003 and still has fans today that consider it one of the finest diesel engines ever produced.

With new, stricter government regulations in place regarding emissions, Ford continued to partner with ITEC—now known as Navistar—to make the 6.0 L Power Stroke. The new engine incorporated several new emissions controls and a variable geometry turbo that boosted power to 325 hp and 570 pound-feet of torque.

It was at this time that the Power Stroke experienced some difficulties in the form of certain failure-prone parts, such as the EGR cooler, high-pressure oil pump, oil cooler, and head gaskets. This impacted the Power Stroke’s reputation of reliability and Ford discontinued it in 2007.

In 2008, Navistar partnered with Ford again, this time to produce the 6.4 L Power Stroke. This new version introduced a common rail system with piezoelectric injectors and a boost that was provided by twin compound turbochargers. The engine produced 350 horsepower and 650 pound-feet of torque. Like the previous engine, however, the 6.4 Power Stroke experienced similar issues such as valve train and head gasket failure.

Although it was a quiet engine that had more power than its predecessor, a common complaint was the comparatively poor fuel efficiency. It stayed in production for only a few years and the partnership between Navistar and Ford ended in 2010.

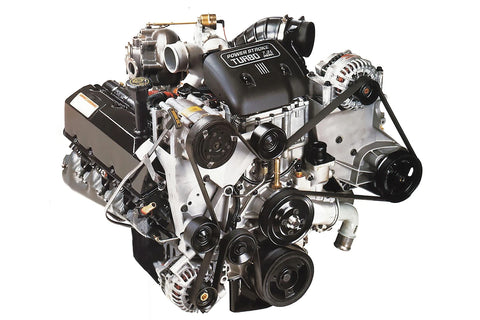

6.4L Power Stroke Engine

Following the end of their relationship with Navistar, Ford went on to produce their own all new Power Stroke. The 6.7 L Power Stroke featured the Instant Start feature and a new design with a water-to-air intercooler and the DualBoost variable geometry turbo. The engine block, composed of compacted graphite iron, was 160 lbs lighter than the 6.4 L. Like its predecessor, it used a common-rail injection system.

In recent model years, Ford has offered the 6.7L in both standard output and a High Output configuration, delivering massive torque for towing and hauling.

In 2018 the Power Stroke brand was expanded to include some light duty diesel applications such as the F150 with the 3.0 Power Stroke. Despite a few missteps, the Ford Power Stroke line of engines continues to be well regarded.

1996 Ford F-350 Power Stroke Turbo Diesel

At-a-glance:

In 1994 the Power Stroke engine was born. Forged out of the experience gained in the IDI (indirect injection) era the all new direct injected, turbo charged diesel featured hydraulic electric unit injectors (HEUI) and ran a high pressure oil pump (HPOP) to create the required pressure for fuel injection.

7.3L Engine

Performance Upgrades:

1999 Ford F-250 Super Duty Crew Cab Long Bed 7.3L

At-a-glance:

With the introduction of the Super Duty came a series of engine updates. These updates included a turbine housing update and a wastegate addition half way through the year. The ‘99 version also continued the use of HUEI fuel injection with upgraded 140 cc injectors—an increase from 120 cc in the earlier model. Now outfitted with larger injectors, the HPOP capability was also increased by using a 17° swash plate angle.

In 1999, Ford introduced an intercooler which enabled an increase in power and decrease in intake temperature and EGTs.

In 2002, powdered metal rods replaced the forged connecting rods of previous models, and while these were adequate for unmodified engines, they could become a serious breaking point for engines pushed above 450 hp.

The reliability of the engine, new bolder body style and stronger chassis has made this era of Power Strokes a highly coveted combination for Ford truck enthusiasts.

Performance Upgrades:

More Reading: The Unforgettable Ford 7.3L Power Stroke Diesel Engine

2006 Ford F-350 Super Duty

At-a-glance:

In an effort to meet stricter government regulations Ford and Navistar teamed up again to develop the 6.0L Power Stroke. In the second quarter of 2003, the 6.0 L began to replace the 7.3 L engine and was used in Ford Super Duty Trucks until 2007 and the Econoline vans until 2009. It featured a 3.74 in X 4.13 in bore and stroke that created a displacement of 5,954 cc. It utilized a variable-geometry turbocharger and intercooler that produced 325 hp and 570 pound-feet torque.

These engines experienced some issues with failure-prone parts. The oil cooler, for example, would plug due to sediment buildup from sand left behind in the block from manufacturing, resulting in high temperatures and engine failure. The sediment also caused a reduction in the coolant flow through the EGR cooler. This would result in premature failure from thermal expansion fatigue in the heat exchanging core.

Premature HPOP failure was also an issue in the ‘03 and ‘04 models, as early HPOP gears proved to be too weak, developing stress cracks in the teeth. This would result in a no-start issue for the engine. ICP sensor failure could also occur, causing Ford to relocate the ICP sensor in a new HPOP design.

Other issues included HPO leaks due to poor quality o-rings, breakage of the prongs of the STC fitting, head gaskets, problems with the Injection Pressure Regulator screen and FICM failures.

In spite of this long list of issues, the venerable 6.0L power stroke has developed a cult following.

Performance Upgrades:

More Reading: Ford's 6.0 Power Stroke Diesel Engine: The Good, the Bad and the Upgrades

2010 Ford Power Stroke F250 XLT

At-a-glance:

The 6.4L Power Stroke engine was a stop gap solution for Ford in an effort to meet tightening emission standards until the launch of the 6.7L Power Stroke. Continuing the relationship with Navistar, the 6.4L was somewhat of a revised version of the 6.0L. Still a intercooled turbo charged V8, it features updates such as; compound turbos, common rail fuel injection and an all new emissions exhaust after treatment system.

Unfortunately the advancement in this engine model came at the cost of other issues. The after treatment system introduced reliability problems that turned into costly repairs for truck owners. These engines also had common head gasket failures, valve train failures and cracked pistons. Thankfully this engine was only in product for 3 model years, making way for the all new update in 2011.

Performance Upgrades:

2022 Ford F450 6.7L Power Stroke Platinum

At-a-glance:

Debuting in Ford’s 2011 all new Super Duty Trucks (F-250 through F-550), the 6.7 L Power Stroke replaced the 6.4 L Power Stroke. This was the first Power Stroke engine developed and manufactured by Ford, designed jointly with AVL engineering in Austria. It features reverse flow aluminum cylinder heads with dual water jackets. Features a high-pressure common rail Bosch fuel system supplying up to 29,000 psi of rail pressure.

6.7L Power Stroke Engine

This engine uses eight-hole piezo injectors to deliver up to 5 injection events per cylinder, per cycle. It also supports fuelling options of up to 20% biodiesel and 80% petroleum diesel. In addition to this new fueling system the 2011-2014 Power Strokes features a dual compressor wheel VGT turbo. This turbo proved to be unreliable and was phased out in 2015 in favor of a conventional VGT turbo. Another unique attribute of the 6.7L Power Stroke is its liquid to air intercooling system replacing the traditional air-to-air system found on previous models.

Among the emission controls are exhaust gas recirculation, Denoxtronic-based selective catalytic reduction (SCR) from Bosch, and a diesel particulate filter (DPF).

The original output was 390 hp with 735 pound-feet of torque, with later factory updates increasing power and torque over time.

Performance Upgrades:

6.7L High Output Power Stroke V8 Turbo Diesel

At-a-glance:

By 2017, the 6.7L Power Stroke engine remained largely unchanged with the exception of packaging and turbocharger updates. With these minor improvements the Power Stroke saw torque and horsepower rise through successive model years as Ford continued to refine the platform.

In current Super Duty applications, Ford lists the 6.7L Power Stroke at 475 hp / 1,050 lb-ft (standard output) and the 6.7L High Output at 500 hp / 1,200 lb-ft (where equipped).

New 2022 Ford F250 Lariat

With a history of durability and performance, Ford's line of Power Stroke engines continue to win over new buyers and impress older fans whose vehicles have endured over the years.

Performance Upgrades:

Quick tip:

If your truck tows often, focus on reliability upgrades first (exhaust flow, sealing, temperature management), then add power. Power is easy—keeping it reliable under load is the win.

Many owners consider the 7.3L (1994–2003) the reliability icon, largely due to its simpler design and long track record. That said, a well-maintained 6.7L is also a strong modern choice with excellent towing capability.

The 6.0L is known for issues tied to the cooling and oil systems and certain emissions-era components. Reliability improves significantly when the known weak points are addressed early.

The 6.4L makes great power, but its higher complexity and repair costs (especially related to emissions hardware and engine durability concerns) can make ownership expensive if problems pop up.

The High Output 6.7L is factory-rated higher and is aimed at maximum towing/hauling performance. Both share the same core platform but are tuned and equipped differently depending on model and configuration.

The 7.3L Power Stroke uses a HEUI system (hydraulically actuated electronic unit injectors) that relies on high-pressure oil to actuate injection—making oil condition and HPOP health especially important.

Yes—when upgrades are chosen with towing in mind. The goal is safe power with controlled heat, smooth airflow, and reliable sealing under sustained load.